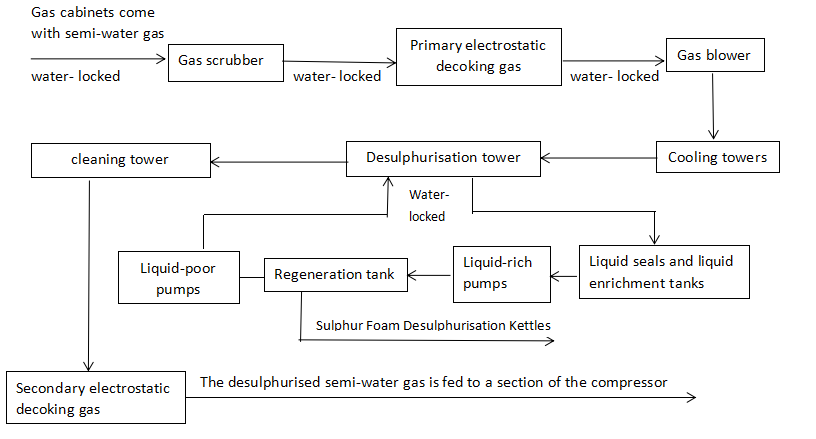

Most of the sulphur in coal enters into the gas phase in the form of H2S during the gas making process, which not only corrodes the process pipeline and equipment, but also poisons the changeover catalyst and synthesis catalyst, so the main purpose of the desulphurisation section is to remove the sulphur in the gas by using DDS desulphurising agent. The half-water gas in the gas cabinet enters the half-water gas desulphurisation tower after electrostatic decoking, cooling and cooling by Roots fan pressure boosting, removing hydrogen sulphide, and then sends to the inlet of one section of the compressor after secondary decoking, cleaning and cooling. The desulphurisation liquid is regenerated and recycled.

Desulphurisation process flow chart for ammonia