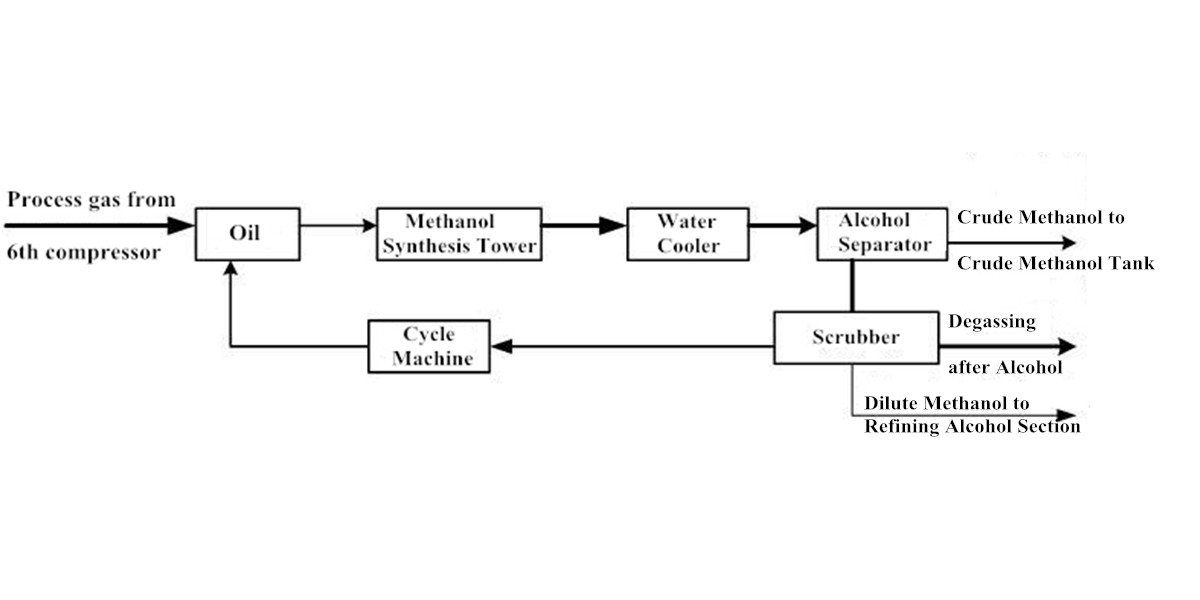

Co-alcohol is a kind of synthesis methanol process. Firstly, it put CO: 1-5%, CO2<0.5%(the content can be adjusted according to the alcohol-ammonia ratio required by production) in the purified gas after transformation and decarbonization and H2 in the gas after conversion and decarburization to pressurize 15MP through the compressor. After reaching 15MP, it goes through the ammonia washing tower, oil fraction, preheater, and waste heat boiler in turn and enters the synthesis tower, where it is synthesized into methanol under the action of the methanol synthesis catalyst. At the same time, it plays the role of gas purification. CO is < 0.5% and CO2 is < 0.2% in the gas after alcohol. The gas out of the tower is cooled to about 40°C by water, and the methanol in the gas is condensed to make the methanol content in the gas less than 0.5%. After the methanol is separated by the alcohol separator, a part of the gas returns to the methanol synthesis tower through the methanol circulator, and the most of the gas enters the refining section.